Laser depaneling opens up a whole new world of opportunities regarding precision, reliability, flexibility and cost efficiency of PCBs.

Laser routing of populated flexible, flex-rigid and thin rigid PCBs significantly reduces the cost of your PCBs. No cutting dyes are needed for flexible PCBs.

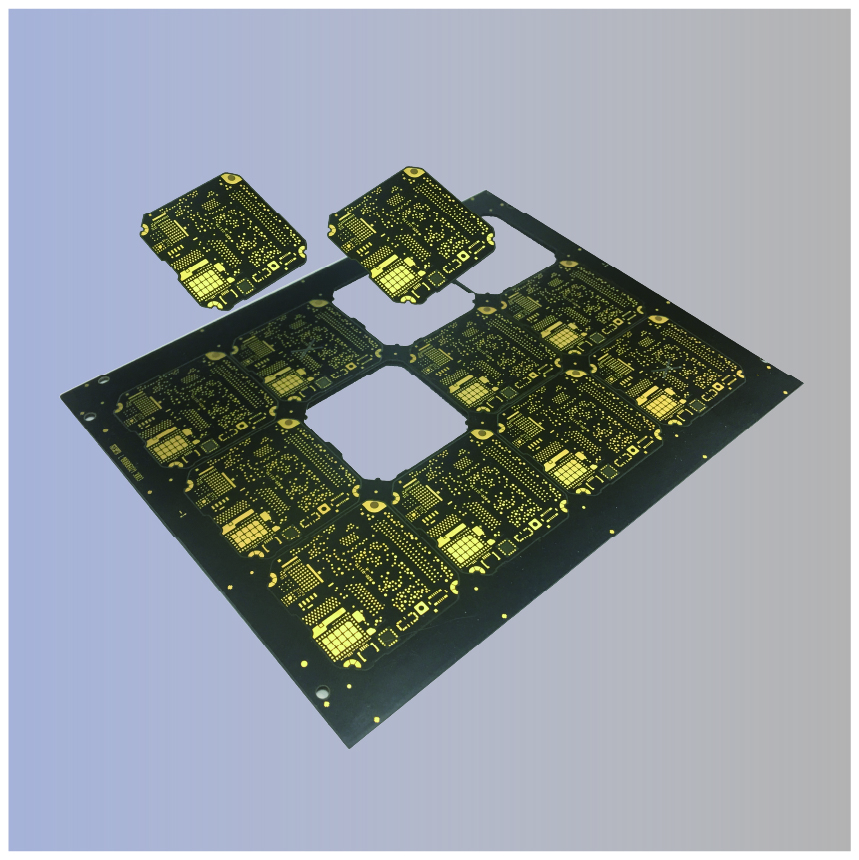

On rigid PCB panels the millimeter wide routing paths for mechanical routers are avoided, so you can place more modules onto each PCB panel for cost reduction.

Laser depaneling of pre-routed rigid PCBs avoids mechanical stress and milling dust to sensitive components and electronic modules and therefore opens up new possibilities in cost-efficient PCB design.

DirectLaser S6 – the standard in depaneling

DirectLaser S6 has become a real standard machine with leading EMS in China.

It is known for its reliability, flexibility, precision, and clean cuts.

The laser router is digitally controlled according to the CAM data of the panel.

Its optical system recognizes the positions of real fiducials, so the deformation of each individual panel can be considered for higher cutting precision.

DirectLaser S6 is available for manual and automatic loading.

The DirectLaser S series comes with different machine designs, working areas and laser power including laser routers for inline material transfer.

The DirectLaser S seriescomes with a CE declaration, verified by an international certification body.